|

PART VI. AVOIDING COMMON ACCIDENTS AND HAZARDS DURING NORMAL

FARM WORKING

A.

Background

After tractor and farm vehicle accidents, the majority of farm

casualties are caused by:

-

People falling from height (off ladders and out of hay lofts

for example)

-

Falling objects (such as stacked hay bales)

-

Electrocution (during the maintenance of generators and other

electrical equipment)

Increasingly though there are other factors causing concern for

the long term health of farmers and farm workers. These include

skin cancer, the effects of heat, and the effects of sustained

vibration and excessive noise levels. In the sections that

follow we provide some general guidance and advice to avoid the

potentially fatal or debilitating conditions that can arise.

B.

Skin Cancer

Exposure to ultraviolet radiation from the sun is the main cause

of skin cancers in Australia. Skin damage from the sun is

cumulative - the longer the skin is exposed to the sun, the

greater the risk of skin cancers, regardless of your tan or skin

pigment.

Rural workers have a high risk of getting skin cancers, as their

work can expose them to long periods of ultraviolet radiation.

Spot the hazard

To help you spot skin cancer hazards, consider:

-

Lack of shade in outdoor work areas.

-

Reflective surfaces, eg water, cement, shiny metal or white

painted sheds and silos, cement surfaces.

-

What

jobs are done in sunlight, and how long they take. What

jobs are done in sunlight, and how long they take.

-

What are the peak sun hours.

-

The day's ultraviolet exposure forecast.

-

What body surfaces are exposed to sunlight.

-

Whether sun blockout is provided or used.

-

Whether protective clothing is available and worn.

Assess the risk

To assess the risk of skin cancer from identified hazards:

-

Work out approximately how long is spent working outdoors each

day.

-

Identify what jobs are normally done in peak sun - between

10am and 4pm.

-

Check whether shade is available for outdoor jobs.

-

Check whether hats, protective clothing and sunscreens are

adequate.

-

Check whether SPF15+ sunscreen is applied to all exposed skin

areas.

-

Ensure sunscreen is re-applied during outdoor work.

Learn to identify various types of skin cancer, and check your

skin for sunspots and unusual pigmentation. The Glossary

contains details on the most common forms of skin cancer

Be aware of short term injury risks:

-

reddened skin, blistering, swelling, and later, peeling of the

skin.

-

photosensitisation - acute skin reaction to UV with certain

drugs, ointments, creams, and chemicals, resulting in

increased sunburn and skin damage.

-

photoconjunctivitis and photokeratitis - sore, red, gritty

swollen eyes, with sensitivity to strong lights.

Long term effects include:

-

Prematurely ageing - wrinkling, wasting skin tissues,

excessive pigmentation, spots marked by clusters of tiny blood

vessels.

-

Cataracts of the eye.

Make the changes

-

Wear cool, protective clothing, i.e. a shady hat, shirt with

collar and long sleeves, and long trousers.

-

Use a sunscreen with a high sun protection factor (SPF +15)

before you go into the sun.

-

Noses, lips, ears, bald heads, necks and backs of hands need

extra protection.

-

Reapply sunscreen regularly, especially if you are sweating.

-

Make use of shade areas wherever possible in the high risk

hours.

-

Use a tractor with shade protection fitted.

-

To safeguard against cataracts, sunglasses that conform to

with applicable standards are recommended.

Early signs

Check your skin for early signs of skin cancer:

-

any unusual skin conditions that don't heal in four weeks;

-

any sore, ulcer or scaly patch on the skin;

-

a white patch on the lips that doesn't heal;

-

any mole that seems to grow quickly;

-

any mole that changes shape or colour;

-

any

mole that bleeds or repeatedly itches. any

mole that bleeds or repeatedly itches.

If you find any of these signs, see your doctor.

Remember

: Over-exposure to the sun's rays increases the skin cancer risk

both now and in the future.

C.

Heat Stress

The effects of heat stress range from simple discomfort to life

threatening heat stroke. Heat stress causes increased sweating

which leads to loss of body fluid and then reduced heat

tolerance. This results in reduced capacity for work,

inefficiency, and increased risk of hazardous incidents.

Heat stroke, a rarer condition, is when sweating stops and body

heat rises. This is a life threatening condition, and requires

immediate medical attention.

Spot the hazard

Heat stress hazards can occur through:

-

high temperatures,

-

high humidity,

-

lack of air movement,

-

unsuitable clothing,

-

a person's lack of acclimatisation,

-

hot protective clothing or equipment,

-

physical activity,

-

radiant temperature of surroundings.

Warnings

Warning signs of heat stress are:

-

tiredness,

-

headache,

-

nausea,

-

loss of concentration,

-

muscle cramps,

-

dizziness.

Assess the risk

Using weather forecasts, availability of shade, knowledge of the

job ahead, and an awareness of individual workers' heat

tolerance, assess whether the day's tasks could cause heat

stress or heat stroke. Consider ways of minimising or

eliminating the risks.

Those most at risk

Working in a hot environment is more likely to adversely affect

people who are:

-

overweight,

-

medically unfit,

-

unacclimatised to heat,

-

unhealthy, particularly if suffering from heart disease,

-

dehydrated, whether from alcoholic hangover, failure to

replace salt and water lost in sweat, or from medically

prescribed diuretic drugs.

Make the changes

Indoors

-

Open windows and doors to allow natural cross ventilation, or

install air conditioning if practicable.

-

Provide fans or ventilators to lower temperature and increase

air movement.

-

Insulate roof, walls or heat making equipment.

-

Duct hot steam and gases outside to help reduce humidity and

lower temperature.

-

Install extraction ventilation around heat producing

equipment.

Outdoors

-

Wear cool cotton clothing to allow air circulation and

evaporation of sweat.

-

Use a broad spectrum sunburn cream with an SPF of 15+.

-

Wear broad brimmed hats that shade head, neck, face and ears.

-

Wear close fitting sunglasses with side shields, labelled to

meet Australian Standard AS 1067.

-

Use a wetted scarf.

-

Provide shaded rest areas.

-

Provide an ample supply of cooled, non-alcoholic drinks and

ensure they are easily accessible.

-

Drink small amounts of water at frequent intervals to avoid

dehydration.

-

Re-schedule heavier work for cooler times of the day or for

cooler days.

-

Where possible, rotate work so workers spend less time each on

heavy tasks.

Heat stroke

If heat stroke occurs:

-

Remove the person from heat and allow to rest in the coolest

available place.

-

Cool the person down with a fine spray of water and fan them.

-

Remove excess clothing.

-

If conscious, give them cool, but not cold, water to drink.

-

Contact a doctor, nurse or first aid officer immediately.

-

Do not give salt or alcohol.

Remember

: If working in hot weather:

-

Replenish lost fluid - take small drinks frequently.

-

Reduce sun exposure during the hottest hours of the day.

-

Rest frequently in a cool place.

D. Avoiding Accidents With Children

Children who live on farms or who come to visit are often at

greater risk than adults who work there. To make your farm safer

for children, hazards must be spotted and risks minimised before

children discover them. The safest farms for children are those

where safety is a priority for everyone.

Spot the hazard

Ask children to help you to spot hazards. Identify places where

children like to play, perhaps where they are not supposed to

be, and the sort of things they might like doing. Consider dams,

streams and pools, silos, tractors, electricity, workshops and

machinery sheds, chemical storage areas, farm bikes, guns and

dangerous stock.

Assess

the risk Assess

the risk

For each identified risk, assess the likelihood and possible

severity of injury or harm. Ask the children to help. Make high

risk areas your top priority for safety improvements.

Make the changes

The following suggestions will help you to minimise risks to

children on your farm.

Fences

-

For small children, have an effective fence around the house

and yard.

-

Fence off septic tanks, sheep dips, seepage pits, ponds dams,

pools and creeks particularly if close to the house.

-

Maintain fences round nearby paddocks and work yards to

protect small children from animals, vehicles, machinery, road

traffic.

-

Have safe, fenced-off areas where children can play.

Workshop

-

Ensure gates, doors and locking systems keep young children

out of workshops and hazardous storage areas.

-

Have safety rules for older children who may need to enter

these areas on farm duties.

-

Keep workshops free from child hazards relating to

electricity, power tools, fire, poisoning, slips, trips, falls

and other dangers.

Pesticides

-

Keep farm pesticides locked away out of children's reach.

-

Fence off pesticide mixing and wash-down bays to prevent

access by children.

-

Keep children out of orchards after spraying.

Silos, grain storage

-

Keep grain storage bins, silos, augers and trucks, adequately

guarded to prevent access by children.

-

Never allow children to play on stored grain in silos.

-

Ensure fixed ladders are guarded and kept above children's

reach.

-

Have rules keeping children out of grain loading and storage

areas unless under close supervision.

Machinery and equipment

-

Lock tractors, trucks and other farm machinery away after use,

out of bounds to children.

-

Electrical appliances and tools should be turned off,

disengaged and kept inaccessible to young children.

-

Keep firearms, ammunition and explosives locked and out of

children's reach.

Protection from animals

-

Have rules to safeguard children from dogs that might attack

or bite.

-

Ensure small children cannot wander into animal pens and

stockyards with confined stock.

Ladders

-

Store ladders away to prevent children climbing roofs, silos,

trees and other height hazards.

-

Ensure fixed ladders on silos, bins, tank stands, windmills

etc. are adequately guarded against children attempting to

climb them.

Emergency first aid

-

Have an emergency plan for dealing with serious accidents.

-

Keep a first aid kit suitable for children, and have someone

trained in first aid.

Do you:

-

Have

a 24-hour safety program for everyone on the farm? Have

a 24-hour safety program for everyone on the farm?

-

Set a good safety example for children?

-

Safeguard children from potential hazards?

E. Avoiding Accidents During Lifting and Manual Handling

Manual handling or strain injuries can keep farm workers away

from work for weeks at a time. They can happen from lifting,

pushing, pulling, carrying, lowering, holding or restraining.

Injuries occur through:

-

increased wear and tear or damage, e.g. from intense or

strenuous manual activity;

-

gradual wear and tear, e.g. from frequent or prolonged periods

of activity (continuous handling of hay bales); heavy or

awkward lifts (lifting heavy machinery onto a ute);

-

sudden damage, e.g. from unexpected movement (carrying a heavy

object over uneven ground, stumbling, tripping or falling).

Spot the hazard

Conduct safety audits of all farm jobs involving manual

handling. Take note of heavy, stressful, awkward or repetitive

activities. Check injury records to see which activities have

caused most strain injuries. Look for difficult handling jobs

that could be made easier.

Assess the risk

Assess the likelihood of each identified hazard resulting in

injury or harm. Use injury records to assess the potential risk

of various tasks. If you consider there is a significant risk of

serious injury, look for the best way to minimise the risk.

Make the changes

Here are some suggestions to help you make the changes:

-

Plan ahead. Consider the safest possible ways of lifting,

carrying, holding, lowering, pushing, pulling.

-

Eliminate

unnecessary tasks. Eliminate

unnecessary tasks.

-

Avoid double handling.

-

Use mechanical aids.

-

Carry out a safety check first.

Lighten the load

-

Where possible, choose light-weight materials.

-

Divide heavy loads into smaller loads.

-

Purchase in smaller bags.

-

Half fill containers.

-

Get help to share the load.

Reduce bending, twisting, reaching

-

Point your feet in the direction of the load you are carrying.

-

Keep

tools and equipment within easy reach. Keep

tools and equipment within easy reach.

-

Build benches to waist height.

-

Keep frequently used items at waist height.

Follow a safe procedure

-

Plan the handling.

-

Clear the way.

-

Wear appropriate protective clothing.

Correct body techniques

-

When lifting a load from ground level, bend knees, keep back

straight, keep load close to your body, lift with leg muscles,

support forearms with knees, and support the load with your

body.

-

When lowering a load, use leg muscles and lower the load by

bending your knees, not your back. Where possible, support

forearms on knees.

Avoid muscle fatigue

-

Warm up first.

-

Take frequent breaks.

-

Change jobs to use different muscles.

-

Gradually get used to the job.

-

Ensure the tractor seat is well sprung.

-

Adopt good posture when standing or sitting at a job.

-

Instead of crouching or squatting for low jobs, use a small

stool.

Mechanical aids

Consider using:

-

trolleys for heavy bags, drums or other weighty, awkward

items;

-

special trolleys to move and tilt 200 litre drums;

-

picket drivers for fencing; *

-

small mobile hoists or forklifts;

-

a fixed hoist on the utility or truck;

-

mobile ramps or skids for loading and unloading trucks or utes;

-

crow bars, barrows, pulleys, hooks and jacks.

Fence picket injuries

Steel fence pickets can inflict nasty injuries on workers using

metal pipe drivers. Unless the pipe section is long enough, the

picket can dislodge at the top of the upstroke, and the

downstroke can bring the worker's arm down on the picket. Make

sure the pipe section is long enough to minimise these risks.

Minimum pipe length should be 600 mm. Take into consideration

the size and strength of the worker. Safe procedure should

include instruction and training to ensure the worker's upswing

does not exceed the length of the pipe.

F. Long Term effects of Farm Noise

Noise from farm tools and machinery can cause permanent hearing

loss. Hearing loss may be temporary at first, but repeated

exposure will lead to permanent damage. The damage can occur

gradually over a number of years and remain unnoticed until it

is too late. Some noises, such as gunshots, are so loud they can

cause immediate permanent damage.

The noise exposure standard for an eight hour day is 90 dB(A).

The exposure standard for peak noise - for example gunshot - is

140 dB.

Spot the hazard

Some early warning signs of hearing loss include:

-

ringing in the ears after work;

-

difficulty understanding a normal conversation;

-

turning up the volume on radio or television when others

appear to hear adequately;

-

failing to hear background noises, such as a ringing telephone

or doorbell.

Typical farm noises that can damage hearing include:

-

tractor (95-100dB(A))

-

header (88-90dB(A))

-

orchard sprayer (85-100dB(A))

-

angle grinder (95-105dB(A))

-

bench grinder (90-95dB(A))

-

chainsaw (105-120dB(A))

-

pig shed at feed time (95-105dB(A))

-

shotgun (over 140 dB(lin)).

Assess the risk

If you have to shout above noise to be heard by someone a metre

away, your hearing could be at risk. If noise cannot be reduced

or removed at its source, and if there is no other way to

separate people from damaging noise exposure, protective hearing

equipment must be worn. Some farmers employ a noise consultant

to take noise readings, assess hearing risks and recommend

preventive measures.

Make the changes

You can reduce noise at its source by:

-

purchasing quieter machinery and equipment;

-

modifying equipment to reduce noise;

-

keeping machinery well maintained;

-

if practicable, running machinery at lower revs.

You can protect people from loud noise exposure by:

-

limiting the time workers spend in a noisy environment.

-

isolating work areas from noisy machinery using distance or

insulation;

-

scheduling noisy work when fewer workers are around;

-

using job rotation to alternate noisy jobs with quiet ones.

Protective equipment

-

Where noise exposure cannot be reduced, hearing protection

should be worn, e.g. on open tractors, when shooting, or when

using a chainsaw.

-

Try on ear muffs before buying, to ensure comfort and a

sound-proof fit.

-

The higher the SLC 80 (sound level conversion) figure for

hearing protection, the higher the protection.

-

Use lower SLC 80 muffs for moderately noisy jobs - a high

rating might mask out important danger warning sounds.

-

Ear plugs may be more comfortable for some farmers, but must

be inserted with clean hands. Re-usable plugs must be cleaned

regularly. Cotton wool is not sufficient.

-

Clean and maintain hearing protectors. Replace worn or damaged

parts. Keep protectors near the area of noisy activity, e.g.

in the tractor cab.

-

Wear a combination of ear muffs and ear plugs when shooting.

Remember

: Once hearing is gone, it is gone forever, and hearing aids are

of little help. They can make speech louder, but they cannot

make it clearer.

G.

Working Safely With Silos

Whenever anyone installs, climbs, enters, fumigates, fills or

empties a silo, significant risks may be involved.

Hazards can include insufficient oxygen, toxic gas, explosive

atmospheres, unguarded machinery, electricity, grain trapping,

silos collapsing, and falls from heights.

There are also significant risks for unsupervised children.

Spot the hazard

Keeping

in mind potential hazard areas, conduct a safety audit of your

silo and grain storage system. Include machinery used in and

around silos, especially grain augers, which can trap limbs and

clothing unless adequately guarded, and are prone to tipping

unless erected and transported safely. Keeping

in mind potential hazard areas, conduct a safety audit of your

silo and grain storage system. Include machinery used in and

around silos, especially grain augers, which can trap limbs and

clothing unless adequately guarded, and are prone to tipping

unless erected and transported safely.

Look closely at any part of the system that could injure or harm

people on the farm, especially children. Check silo ladders,

both external and internal, edge protection, and safe procedures

for fumigation, dislodging bridged grain, and rescuing somebody

trapped inside.

Assess the risk

Check whether identified hazards present risk of serious injury,

and consider ways risks can be minimised.

Make the changes

To help farmers make the necessary safety changes, here are some

suggestions:

-

Remember, grain dust in silos can be become explosive,

particularly if humidity is low.

-

Don't smoke near silos, and avoid causing sparks from metal

friction or electric switches.

-

Carbon dioxide in a silo can displace oxygen and cause

suffocation.

-

High temperatures can cause heat stress for people inside a

silo.

-

Do the job from outside if possible.

-

Wear respiratory equipment when appropriate.

Safe fumigation

-

Ventilate fumigated silos before entering.

-

Always follow the manufacturer's recommended safe ventilation

period.

-

Open phosphine containers in the open air, not in the shed or

silo.

-

Hold the container away from your face, and position yourself

upwind.

-

Wear protective clothing and equipment.

-

Have someone standing by when fumigating.

-

Place phosphine tablets into the silo from the roof using a

tube.

-

Clearly mark all areas under fumigation with "DANGER UNDER

FUMIGATION" signs.

Avoid grain suffocation

-

Don't enter a silo unless you have to.

-

If you enter a silo, have someone standing by in case of

difficulties.

-

Never enter a silo without turning off the auger and ensuring

no-one can start filling or emptying the silo while you are

inside.

-

Stay on the ladder above the level of compacted or bridged

grain while dislodging it.

-

Ensure external ladders start at a height inaccessible to

children.

Check machinery

-

Guard auger drive train (belts, pulleys, drive shafts) and the

rotating screw fitting.

-

Locate mobile augers on firm, preferably flat ground, and

operate at a shallow angle (less than 45deg) to prevent

overbalancing.

-

Lower mobile augers when transporting.

-

Never start augers hidden from your view before checking the

area is clear of people.

Avoid structural failures

-

Every stored material has different structural characteristics

- a silo designed to store one product may not be suitable for

another. Care must be exercised whenever a new product is

stored in a silo.

-

Follow manufacturer's instructions exactly in preparing the

concrete pad.

-

Use "bedding-in" procedure when filling a silo, by drawing off

a rubbish bin full of grain.

-

Keep people, specially children, well clear when filling or

emptying a silo.

-

Seemingly simple changes to a silo can drastically alter its

structural stability. Consult an engineer before any

alterations are made. Equipment attached to silos can also

impose dangerous loads.

Avoid falls

-

Provide roof fall protection in the form of a simple edge

rail.

-

Install an external ladder cage where required.

-

Provide a permanently hinged wire mesh guard on all external

openings above the maximum level of grain.

-

Use a safety harness.

Emergency procedures

-

If trapped by grain don't panic - the grain will pack tighter.

Shield your face and chest with arms and clothing to create

space for breathing.

-

Plan your escape. Always have a person watch from the outside.

The watcher should have clear instructions what to do in an

emergency. The first instruction is: "Don't follow me in."

-

If only one person is on standby and cannot pull you out

without entering, they must call for help. Only then may

someone enter, wearing a breathing apparatus and a life-line.

One or more people outside can help to pull you out.

-

If someone else is trapped in a grain silo, empty the bin by

opening any side outlet, then cut flaps in the cone or walls

all around the base using power tools.

H.

Dangers From Hay Baling Operations

Large hay bales, some weighing up to 800 kg, have killed and

seriously injured many farm workers in Australia. Bales, both

round and rectangular, can fall on tractor and forklift

operators , topple off stacks and vehicles on workers or

bystanders, and collapse when stacks fail.

Spot the hazard

Look for hazards relating to:

Handling:

-

Children playing near hay balers, carriers and stackers.

-

Training of operators handling tractors, front-end loaders or

forklifts.

-

Use of two-poster tractor ROPS for baling - they offer no

operator protection from bales falling back off forks or

bale-loading frames. Tractors with cabs, FOPS (fall on

protective structure) or four-poster ROPS are safer.

-

Makeshift or poorly fitting bale-loading attachments on

tractors and forklifts.

-

Carrying bales too high off the ground.

-

Insufficient counterbalance on tractor or forklift vehicle.

-

Hydraulic control valve should be specific to the front-end

loader attachment.

Baler operation:

-

Baler properly connected to the tractor.

-

Adequate safety guards fitted.

-

Nobody allowed to ride on the baler.

-

Prevent others getting too close to the baler.

-

Build-up of loose, combustible material in the baler.

-

Fire extinguisher fitted to the machine.

-

Disengage PTO and apply fly wheel brake prior to making baler

adjustments.

-

Stop engine and apply fly wheel brake before repairs or

"stringing up" the baler.

-

Extra care and attention when reversing or turning the

machine,

-

working at night,

-

loading onto a truck, and unloading.

Stacking:

-

Loading and stacking on uneven ground.

-

Stacks under or near overhead powerlines

-

Stacks of round bales inadequately chocked and border posted.

-

Damaged bales at base of stack - eg from vehicles, cattle or

rodents.

-

Unstable heights and loose stacking.

-

Bales stacked higher than safe operating height of farm

tractor or forklift.

-

Children playing on stacked bales, particularly during

stacking or unstacking.

-

Lack of training, experience and protection for people doing

hay baling, stacking and loading.

-

Handling more bales than safe for the loader.

Transporting:

-

Sturdiness of trailers carrying heavy loads of bales.

-

Restraining frames back and front of trailer.

-

Hooks fitted so ropes can be used to secure load.

-

Roads too close to or below powerlines.

-

Rough terrain causing bales to become unstable.

-

Safe speeds at all times.

-

People riding on loaded hay trailers - highly dangerous.

Assess the risk

Check each hazard that has been spotted to assess:

-

Likelihood - how likely is this hazard to injure someone? and

-

Severity - how severe would that injury be?

List all the hay baling and stacking hazards spotted, and number

them in order of priority, so that those most likely to cause

injury or harm can be tackled first.

Because most large hay bales can kill or seriously injure anyone

they fall or roll on, any risk of a hazardous incident should be

assessed as requiring urgent attention. And as children are the

most vulnerable, consider child injury risks top priority.

Make the changes

Handling:

-

Keep children away from hay baling and stacking operations.

-

Make sure operators and handlers are properly trained and

physically capable of tasks.

-

Consider fall-arrest protection for people working at heights.

-

Use tractors with four-poster ROPS, FOPS or cabs for

protection against falling bales.

-

Replace risky attachments with manufacturer approved

attachments.

-

Ensure loader or forklift operators transport bales close to

the ground.

-

Avoid sharp turns and unsafe speeds.

-

Make sure vehicle controls are fitted specifically for the

attachment in use.

Stacking:

-

Stacks should be on firm, level ground, away from fire

hazards, sources of ignition, overhead powerlines, dwellings,

boundary fences and footpaths.

-

Make sure stack and load heights do not exceed the lifting

capabilities of the farm handling equipment.

-

Big bales should be stacked to a maximum of four bales high.

-

High density bales can be stacked up to six layers high.

-

Wherever possible, stack big rectangular, square or high

density bales by overlapping, to form a stable stack.

-

Do not use bale lifting equipment to raise people on or off

stacks.

Transporting:

-

Do not allow people to ride on stacked trailers.

-

Be aware of overhead obstructions, like trees, bridges and

powerlines.

-

Avoid rough ground that could cause bales to dislodge.

-

Ensure loads are adequately secured.

-

Do not overload vehicles beyond legal limits.

I.

Protecting Yourself When Fire Fighting

Teamwork, planning and communication are vital to the safety of

people fighting fires, burning off or doing other fire

prevention work.

Spot the hazard

The main hazards are smoke inhalation and radiant heat.

Associated hazards relate to training and safe fire fighting

practices, communication between firefighters, other people

involved, wind and weather conditions, terrain and vegetation,

threatened buildings and their contents, availability of water

and fire fighting machinery.

People on farms should know how to contact the area fire control

officer.

Assess the risk

Safe fire fighting procedures involve constantly assessing risks

and their potential to endanger life and property, and

minimising them where possible.

Make the changes

The following safety rules help firefighters minimise risks.

-

Never work alone.

-

Anticipate fire changes due to wind, topography and fuel type.

-

Watch for erratic fire behaviour.

-

Beware of burning limbs and trees in previously burnt country

- look up and live.

-

Keep clear of all vehicles or machinery - the operator may not

see you.

-

Avoid steep slopes above a fire.

-

Observe and keep in mind local topography:

-

the position of tracks, clearings, creeks and other relevant

spots or landmarks

-

avoid danger areas like steep slopes, dense vegetation and

deep, narrow gullies.

-

Select escape routes before entering the fire zone.

-

Obtain the latest forecast with particular attention to wind

changes.

-

Remember a general forecast may not apply in your area due to

fire effects, terrain or local factors.

-

Relate local weather to possible fire behaviour.

Personal effort

-

Maintain self control under threat situations.

-

Panic is infectious and drains energy.

-

Avoid exhaustion from over-exertion or prolonged periods of

effort.

-

Avoid unnecessary shouting or whistling - it may confuse

others.

Limits of endurance

-

Lack of rest reduces physical strength, the ability to think

clearly and speed of reactions - arrange relief for yourself

and your team.

-

Take a break at every opportunity.

-

If feeling ill, drowsy, faint or nauseated, take action for

heat stress.

Drinking

-

To do without water for long periods is a mistake. Dehydration

can make you sluggish, irritable, impatient, muddle-headed,

tired and sleepy.

-

When sweating freely, replace body fluids and salts. Drinking

small quantities frequently is better than having one big gulp

every hour.

-

Replace salt by taking salt in food and drink, e.g. Vegemite

or lightly salted water (one level teaspoon per litre).

-

Aerated drinks blow up the stomach and make hard work

uncomfortable. Beer does not help either.

-

No alcoholic drinks. Wait until the fire is finished before

'one with the boys'.

Protective clothing

-

Guard against falling objects - wear an approved safety

helmet.

-

Make sure your helmet is properly adjusted. In severe

conditions, wear a chin strap.

-

Wear safety glasses, goggles or a face shield to prevent

injury from windblown dust, smoke irritation or during

chainsaw operations.

-

Working boots must be in good condition. Wear approved safety

boots.

-

Woollen clothing offers some protection against fire.

Heat and smoke

-

Protect against radiant heat.

-

Take refuge:

-

light a back burn and use burnt country as a refuge;

-

use gravel pits, or clearings in the forest and roads;

-

lie down on the ground - air is freshest and coolest at

ground level.

-

Use vehicles to shelter from radiation when the temperature

becomes uncomfortable.

-

Don't take refuge in elevated water tanks. Immersion in

lukewarm water can kill.

-

Limit breathing rate when smoke is dense - wait for small

pockets of fresh air.

-

Dense hot smoke could damage lungs, but hot dry air can be

breathed for some time without lung damage.

-

If it is necessary to move through the flames:

-

don't linger in front of the flames;

-

use clothing to the best advantage as a shield;

-

select an opening where flame height is lowest;

-

move through the flames onto burnt ground as quickly as

possible;

-

beware always of the danger from falling limbs and trees in

burnt country.

-

As a last resort, if trapped, lie on the ground taking

advantage of any protection available.

Be sure to:

-

Beware of falling limbs and trees.

-

Know the local topography.

-

Drink plenty of fluids.

J. Long Term Effects of Whole Body Vibrations

Introduction:

In the UK research by the Government’s Health and Safety

Executive has shown that operators of self-propelled

agricultural machinery are exposed, for half of all working

days, to whole-body vibration, at levels which can cause severe

discomfort and a risk of back injury (see Glossary for more

information). The most widely reported WBV injury is back pain.

Prolonged exposure can lead to considerable pain and time off

work and may result in permanent injury and having to give up

work.

Note:

There are many sources of back injury in addition to WBV which

must be adequately controlled if risk of back pain and injury is

to be minimised.

What

should be done?:

Much can be done to reduce WBV.

Decide

who is at risk:

Drivers using tractors or mobile agricultural machinery for long

periods of time are at risk. Table 1 may help you decide when

drivers are likely to be at greatest risk. If the actions

suggested below have been taken, you may wish to have WBV

exposures measured to help decide if any more action is

appropriate.

Reducing the risk of WBV injury:

The following actions are suggested to help reduce the risk of

WBV injury:

Inform:

Drivers can control their exposure to WBV when they know the

risks and the steps they can take to reduce their exposure.

Steps include:

-

making full and proper use of seat position and suspension

adjustments - drivers should be able to easily reach the

pedals, know how to use any back support, adjust the seat so

it provides support for their thighs and adjust the suspension

mechanism correctly for their weight.

-

choosing a speed appropriate for the ground they are driving

over - control of WBV should be used to reduce the risk of

injury, NOT increase productivity.

-

selecting a course to avoid potholes, ruts, bumps, etc as much

as possible.

Maintenance:

Engineering control of WBV exposure largely depends on

suspension systems. Seat, cab and chassis suspensions should be

checked and lubricated and maintained as recommended by the

manufacturer.

Suspension seats often have a working life shorter than that of

the vehicle they are fitted to. It is essential that the seat is

kept in good working order and is replaced when worn out. The

vibration dampers in the seat can wear out and these may need to

be replaced during the working life of the seat.

Maintain tracks, etc to a high standard to make them smooth as

possible.

Selecting machinery:

Manufacturers have a duty to supply machinery (but not

agricultural tractors) with low vibration emissions and inform

buyers of the WBV emission level. Choose equipment with low WBV

emission levels but only compare levels if the measurements have

been made using the same method. Ask suppliers for additional

information such as likely vibration emissions for the work the

vehicle is most likely to do.

Agricultural tractors must be fitted with seats that have passed

a vibration test but there is no legal duty to provide further

information.

Suspensions:

Some vehicles have cab or chassis suspension in addition to or

in place of seat suspension, that will reduce exposure to WBV.

Check with the supplier that the suspension(s) fitted will

reduce WBV in the intended application(s) - suspensions can

amplify vibration if used in the wrong circumstances!

Suspended seats need to be properly adjusted to the middle of

the suspension range for the driver's weight - some seats are

self-adjusting.

The

vehicle should not be driven so fast that the suspensions reach

the end of their travel and hit end stops, causing jolts that

may injure the user.

Job

rotation:

In some circumstances it may be appropriate to share driving

activities among the workforce but beware of increasing the

numbers exposed to risk.

Symptom

reporting:

Encourage workers to report back injuries and any back pain so

that you can take action to stop it getting worse.

You can

get further information from your local HSE office. The address

is in the phone book listed under Health and Safety Executive.

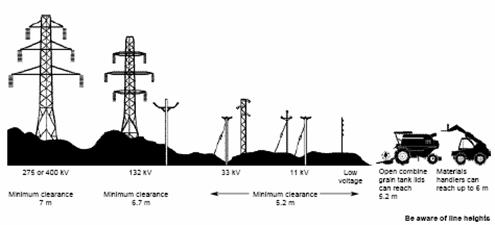

K. Overhead Power Lines

Introduction

In

the UK, about five people are killed every year in accidents

involving overhead power lines (OHPLs) during agricultural

work. Machinery (like combines, tipping trailers, boom

sprayers, loaders); equipment (such as irrigation pipes and

ladders); and activities (eg stacking) are often involved.

Contact with the lines does not need to be made. Electricity can

flash over when machinery or equipment gets close to overhead

lines. Most incidents involve high-voltage lines supported on

wooden poles, but the dangers of other power lines such as those

supported on steel towers or steel poles and concrete structures

cannot be ignored.

Planning precautions

-

Consult your local electricity company and /or your National

Grid Company for lines on steel towers operating at 275 and

400 kV.

(The operating voltage will be displayed on a sign attached to

the tower.) They will provide free information and advice

about precautions and safe working procedures which can be

followed near power lines.

-

Find out

the

maximum height and maximum vertical reach of your machines and

those used by contractors.

-

Find out

the

routes of all

overhead lines on your land or near your boundaries. Mark

them on the farm map. The electricity company should give you

this information.

-

Make sure

you

have information about all the lines on your land - if not,

contact the owners of those lines.

-

Make sure

you

have details of the maximum working heights permitted under

each span of overhead line on your farm and adjacent to each

structure. Mark these on the farm map. The farm map can be

used as a reference when planning cropping or other work,

instructing machine operators and contractors, or buying new

equipment. In cases where there is a significant risk, it is

sensible to discuss the following measures with the

electricity company:

-

Access:

creating alternative access points and routes - this is often

the cheapest option.

-

Divert lines:

benefits can arise from burying lines or changing routes - an

option particularly suited to farmyards.

-

Barriers and goalposts:

by erecting “goalposts” and barriers, machines which have to

pass beneath lines can be limited to a safe height – an option

especially suited to gateways and tracks.

Selection of machinery

The

risks of contact or flashover can be greatly reduced by

selecting machinery that will not reach more than 4 m

from

the ground. Check the working heights of your machines and the

maximum heights that folding elements can reach. Check with the

manufacturer or supplier if necessary.

Use of machinery

Accidents can be prevented if the following operations are

not carried out

within a horizontal distance of at least 9m from power lines on

wooden poles or at least 15m from lines on metal towers. These

distances should be measured from the line of the nearest

conductor to the work, projected vertically downwards onto the

floor, and perpendicular to the route of the line. The

operations are:

-

stacking bales or potato boxes;

-

folding sprayer booms;

-

tipping trailers or lorries;

-

operating materials handlers;

-

working on top of combines or other high machinery.

Risks can be reduced by:

-

using sprayers with horizontally folding booms;

-

never folding sprayer booms on the move;

-

taking care not to damage poles and stays;

-

making sure machinery can operate safely near any overhead

lines;

-

fitting shorter radio aerials or repositioning existing ones

on high machines so they cannot cause danger;

-

carrying irrigation pipes horizontally using two people and

not storing pipes or other materials and equipment near or

under power lines and their supports;

-

designating safe areas for high-risk operations, eg boom

folding, telescopic handler use, tipping trailers.

Working safely

Key

elements of safe systems of work are:

-

Training:

Everybody who works near overhead power lines with a machine

or equipment needs to know what the dangers of overhead lines

are, the precautions to follow and what to do if they do

contact a power line.

-

Visitors:

Contractors are at risk when they work on farms where overhead

lines are present. Make sure they know where the lines are and

tell them the precautions they need to take. Routes can be

marked with safety signs to warn all visitors of the dangers.

EMERGENCY ACTION IF THERE IS AN ACCIDENT

-

Never touch an overhead line - even if it has been brought

down by machinery, or has fallen. Never assume lines are

dead.

-

When a machine is in contact with an overhead line,

electrocution is possible if anyone touches both the machine

and the ground. Stay in the machine and lower any raised

parts in contact or drive the machine out of the lines if you

can.

-

If you need to get out to summon help or because of fire, jump

out as far as you can without touching any wires or the

machine - keep upright and away.

-

Get the electricity company to disconnect the supply. Even if

the line appears dead, do not touch it - automatic switching

may reconnect the power.

Safety representatives

When

assessing the risks from OHPLs, talking to your employees about

how they do their work can be very valuable. Use trade union or

other employee safety representatives to help you. |